The Ultimate Guide to Buying a Wood Splitter

When the job is firewood, you don’t cut corners, and you don’t waste time with tools that can’t keep up. A quality wood splitter isn’t a luxury; it’s a necessity. It’s the difference between wasted effort and efficient output. Whether you’re heating your home,

managing a rural property or processing cords for resale, the right machine delivers consistency, power and a serious return on investment.

This guide was built with real-world users in mind. We’ll walk through how to choose the right tonnage, what to expect from gas vs. electric models and which features actually matter when it comes to long-term performance.

If you’re looking for a machine that’s engineered to split harder, work longer and simplify your process, you’re exactly where you need to be. At Axe Master, we build machines as tough as the people who use them, crafted for high performance and built

to last. For anyone looking for a dependable, high-output wood splitter Canada can count on, this guide covers everything you need to know.

Why Invest in a Wood Splitter?

Splitting by hand has its place. But when you’re dealing with dense hardwoods, frozen logs or volume that piles up fast, an axe won’t cut it, not against the long Canadian

winters.

That’s where a wood splitter changes everything, it brings control, consistency and serious time savings to the process. It processes logs cleanly and evenly, reducing the

risk of injury and strain. And because it doesn’t rely on human power, you get predictable performance regardless of temperature, terrain or time of day.

You can move through big piles of hardwood in a fraction of the time without sacrificing quality or control. One operator can move through cords of firewood with ease, even in cold or remote conditions.

For homeowners, that means firewood when you need it, no delays, no borrowing equipment. For firewood suppliers, it’s a commercial advantage. And for anyone working off-grid or in variable weather, it’s peace of mind.

If you’re investing in a wood splitter, you’re investing in independence and a machine that should work just as hard as you do.

Axe Master machines are designed and manufactured in-house to meet the needs of real users Built for Canadian conditions, built for performance and built to last.

Types of Wood Splitters: Built for Real-World Use

Choosing the right wood splitter starts with understanding how you work. It’s not about bells and whistles, it’s about performance, durability and matching the machine to your workload. From compact electric units to commercial gas-powered splitters, there’s a

right fit for every job.

Here's a breakdown of the three most common types and what each one is built to handle:

1. Electric Wood Splitters

If you're working with smaller logs, don’t have huge volumes to process and easy access to power, an electric wood splitter gets the job done with minimal noise or mess and requires very little maintenance. It is perfect for splitting seasoned firewood in your garage or backyard.

- Best for: Light-duty residential use

- Pros: No fuel required, low maintenance, easy to operate indoors

- Cons: Limited power, requires access to electricity

Electric units are efficient for small jobs, but they’re not designed to take on frozen hardwood or volume work.

2. Gas-Powered Wood Splitters

These are the backbone of serious firewood operations. Gas splitters deliver the high torque needed to cut through large, frozen or knotted logs without hesitation, faster cycle times and the freedom to work wherever you need. They are built for volume and

come in a wide range of tonnages from 20 to 40+ tons. They're portable, built tough and designed for daily use in any weather.

- Best for: Acreage owners, forestry work (remote or high-volume applications), firewood sales.

- Pros: High torque, mobility, built to power through dense, knotted, or frozen logs

- Cons: Requires fuel and regular engine maintenance, louder than electric models

Axe Master specialises in this category. Our machines are built for performance and simplicity. With fewer moving parts and faster output, they can process up to 4 full cords per hour without slowing down.

3. Hydraulic Splitters (Electric or Gas)

Hydraulic wood splitters use controlled pressure to push logs through a steel wedge. Whether electric or gas-powered, hydraulics provide consistent force and clean splits, every time.

Look for features like:

- Fast cycle times (10-15 seconds)

- Auto-return functionality

- Adjustable log tables or cradles for safe handling

- Dual-direction splitting

Hydraulics make splitting safer and more consistent. The fewer moving parts, the less you need to worry about downtime. At Axe Master, every detail from control placement to cylinder strength is designed with output and operator ease in mind. Our systems are streamlined, reliable and ready to work season after season.

Tonnage Matters: Match the Power to Your Wood

When it comes to choosing a wood splitter Canada customers can rely on, power is not a maybe, it’s a must. Not all logs are created equal, and not all splitters are built to handle them. One of the biggest mistakes buyers make is underestimating just how much force they’ll need. Tonnage isn’t just a number. It’s the difference between slicing through a knotted hardwood round in seconds or fighting with a stalled machine.

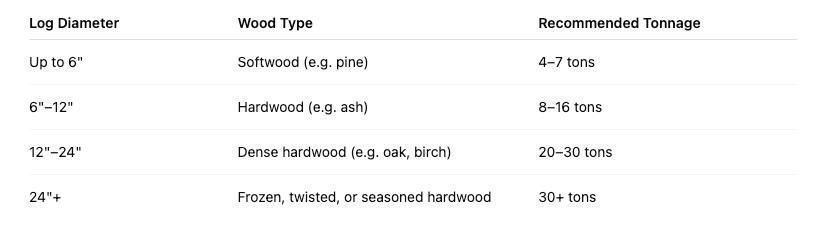

The right tonnage depends on three things: wood type, diameter and whether you're working with seasoned or green timber. Cold, frozen rounds require even more muscle. The key is to match the machine to your wood, not the other way around.

Here’s a quick breakdown to guide your decision:

Whether you’re splitting dense hardwoods like maple, birch or elm throughout the season or tackling frozen, oversized rounds in colder or remote environments, you need a machine built for the job. This is where high-tonnage gas models stand out.

You don’t just need a splitter that can do the work; you need one that powers through without hesitation. That’s exactly what Axe Master delivers. Our hydraulic systems are engineered for continuous performance, and every unit is field-tested to handle the toughest conditions with ease.

Horizontal vs. Vertical: What’s the Difference and

Which One Do You Need?

When selecting a splitter, configuration matters and has a big impact on how you work. The way your machine handles logs can directly impact safety, efficiency and overall output, especially when you're working alone or processing larger rounds. Horizontal and vertical setups each have their place, and knowing the difference helps you choose the right machine.

Horizontal Splitters

Most standard models operate horizontally. You lift and load the log onto a fixed beam, and the wedge drives through it in one direction. It’s a straightforward setup that works well for smaller to mid-size logs, with faster handling and less repositioning.

Ideal for: Consistent-sized logs, day-to-day use, fast production

What to expect: Waist-height loading, quicker handling, better visibility during operation

Vertical Splitters

Vertical units are built to tackle the heavy stuff. Instead of lifting oversized logs, you roll them into place and split them right on the ground. The wedge pushes through the wood from above. This setup reduces strain, and it’s a smart option if you’re working solo or handling logs that are too bulky to lift safely.

Ideal for: Oversized, irregular or frozen rounds that are difficult to lift and require ground-level access.

What to expect: Ground-level splitting, slower handling, but much safer for large or oversized logs

Dual-Mode/Combination Units

Some models allow you to switch between horizontal and vertical modes. This adds flexibility to your setup and lets you adapt to different log sizes, wood types, or job site demands without compromising performance.

At the end of the day, it’s about choosing a setup that works the way you do. Axe Master machines are built for output, safety and simplified handling, whether you’re stacking for the winter or feeding a business.

Portability and Placement: Designed to Move with You

Splitting wood in one place is rare. If your firewood operation moves from job sites to bush lines to backwoods roads, your splitter needs to move with you. Portability isn’t optional. It’s how you stay productive, wherever the work takes you, and your splitter needs to travel just as well as it works.

Here’s what to look for in a mobile setup:

- Towable frames with road-ready tires and solid axle construction

- Compact dimensions that load easily onto trailers or fit through narrow access points

- Heavy-duty wheels that handle snow, mud, gravel and uneven terrain without getting stuck

Axe Master wood splitters are made for movement. They're easy to transport, quick to set up and built to handle the rough terrain that comes with real outdoor work, no matter the season.

Features That Make a Difference

Not every splitter is built equally. It’s the design details, they’re what keep you working smarter, not harder. These upgrades don’t just save time. They protect your back, speed up production and reduce the strain that comes with tough jobs. They separate a decent machine from a dependable one.

- Log Lift Attachments - No more deadlifting massive rounds. Ideal for large, awkward rounds.

- 4-Way Wedge - Split logs into quarters in a single pass, reducing your cycle time by half. Great for bulk processing and cleaner stacks.

- Auto-Return Cylinder - Reset the ram automatically, keeping your workflow smooth and fast.

- Custom Controls Layouts - Easy-to-reach levers and safety shutoffs

- Extended Log Tables - For catching and stacking split pieces, without chasing them to the ground.

Investing in thoughtful features increases both your productivity and your safety. At Axe Master, we design with the operator in mind. Every feature has a purpose, and every part plays a role.

Maintenance Tips for Long-Term Performance

A good splitter is built to last, but like any piece of machinery, it needs regular attention to stay sharp, safe and ready to work. Because it runs under pressure, in rough conditions and often for long stretches, staying ahead on maintenance means fewer breakdowns, less downtime and a machine that delivers season after season.

Here’s what to keep on your checklist:

- Hydraulic Fluid - Check levels often and top up when needed

- Bolts & Hoses - Tighten and inspect for wear or leaks

- Wedge - Keep it sharp for clean, efficient splits

- Air Filters & Fuel Tank - Clean filters and drain fuel before winter storage

- Moving Parts - Apply grease where it counts

Axe Master machines are designed and engineered for low-maintenance operation and performance, but keeping a basic checklist ensures years of dependable use.

Safety First: Best Practices

Wood splitters are powerful tools, and safety is non-negotiable. It’s a machine with serious force behind it, sharp blades and moving parts. A few simple habits can prevent accidents and keep your work running smoothly.

Use common sense and protective gear:

- Wear the right gear - gloves, safety glasses, and sturdy footwear are non-negotiable

- Keep your hands clear of the splitting zone at all times, and always use the controls

- Avoid loose clothing that could get caught in the machine

- Watch your footing, never run the splitter on unstable or uneven ground

- Don’t disable or ignore safety guards - they’re there for a reason

- Stay clear of moving parts - no distractions

Training anyone who uses the machine, even occasionally, will reduce the risk of accidents.

At Axe Master, safety isn’t just a feature; it’s built into the way our machines are designed. But even the most reliable equipment needs a focused operator behind it.

Why Choose Axe Master?

Axe Master machines are built to do more than just split wood; they’re built to last. From frames to hydraulics, every model is designed, engineered and assembled with Canadian conditions in mind. Whether you’re splitting firewood for the season or running a full-scale operation, our machines deliver unmatched value, durability and ease-of-use.

What sets us apart:

- Fast cycle times with industrial-grade hydraulics

- Output capacity of up to 4 cords per hour

- Fully customizable builds tailored to your specs

- Towable designs for easy transport and field setup

- Reliable support with service parts and post-sale care

Customers trust us not just for the product but for the performance.

If you’re searching for a wood splitter Canada operators trust for power, longevity and low maintenance, look no further. Axe Master is where quality meets performance.

Buying a wood splitter isn’t just about saving time; it’s about getting consistent results, season after season. At Axe Master, every build is engineered for performance and backed by real-world experience. When you invest in the right splitter, you get more than speed; you get a machine that won’t quit when the job gets tough.

From backyard setups to commercial-scale output, we’ve got a model that fits your needs and a team that’s here to support it long after delivery.

Visit www.axemaster.ca to explore our lineup and find the splitter that’s built to work as hard as you do.